As a result of the development of technology, old types of steering wheels have been replaced by new types of power steering.

This feature is now a standard in almost all vehicles produced today. Hydrolic wheel; It is a system produced as a support for parking in narrow spaces and traveling comfortably on winding roads where we need to turn the steering effectively and frequently.

For this reason, traveling with vehicles with hydraulic steering request prevents accidents as it does not tire the driver.

WHAT IS A HYDRAULIC STEERING?

As in the old style steering, when you turn the steering wheel to the right or left in power steering, the steering wheel rotates with the effect of the drive of the oil pumped with the help of a pump.

Since the hydraulic system is used instead of mechanical components in this system, it offers a lighter tour than normal steering.

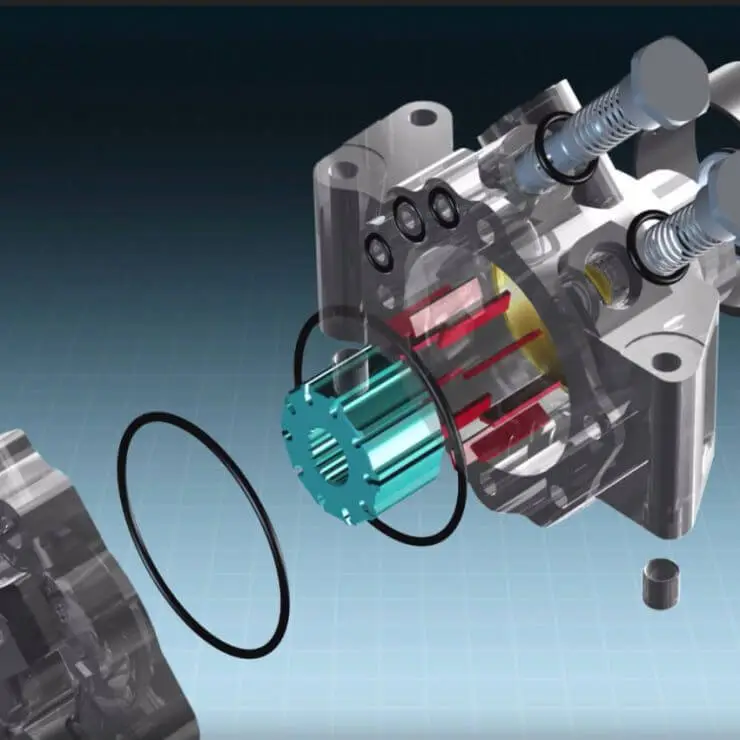

WHAT ARE THE COMPONENTS OF THE HYDRAULIC STEERING?

1 - Steering wheel

2 - Steering column

3 - Steering gear box

4 - Steering shock absorber

5 – Command arm

6 - Rods and tie rods

7 - Steering hydraulic pump

8 - Steering knuckle

9 - Idle arm

WHAT ARE THE BENEFITS OF THE HYDRAULIC STEERING SYSTEM?

- It minimizes the energy consumption used by the driver to turn the steering wheel.

- Provides more turning angle of the steering wheel with less steering movement during maneuvering.

- When the tire of the vehicle punctures, it prevents the steering wheel from getting heavy and loss of control.

- Provides ease of maneuver in short and narrow spaces, thus providing more comfortable parking

WHAT ARE HYDRAULIC STEERING FAULTS?

Almost all of the parts listed above in the steering system components section may fail.

However, if we make an analysis in general; the most faulty parts; steering gear and steering pump.

Since these parts are actively used continuously in the system, they are more susceptible to wear and deterioration.

Among these two components, especially the steering gearbox is the most malfunctioning part.

This part can be repaired, but the failure is likely to recur over time.

WHAT MUST BE DONE TO AVOID STEERING FAILURE?

- Turning the steering wheel while the vehicle is at a standstill damages the tie rods and tie rod ends, therefore do not turn your steering wheel while the vehicle is at a standstill.

- Check your steering hydraulic oil frequently. Lack of oil in the movable parts in general disrupts the operation of the system and may damage the system.

- Have the shock absorbers maintained and replaced regularly, if necessary.

- Do not turn the steering wheel to the last point when you turn the steering wheel full turn. Because in such cases, the risk of malfunction increases as the steering oil pump will be forced more than necessary.

How is power steering repair done?

First of all, the defective part should be detected due to the fault detection.

Accordingly, defective power steering parts should be replaced with new ones or repaired.

Hydraulic Steering Troubleshooting How to do?

Power steering malfunctions are found by testing all components of the system individually using a steering tester.

Therefore, professional Steering wheel revision centers and repairers should use a proven device in this regard.

WHAT IS THE ELECTRIC STEERING SYSTEM?

In fact, the electric steering system is a further development of this system, which can also include the power steering system.

This system has become quite common today. The biggest factor in the widespread use of the electric steering system; lower fuel consumption, less parts and maintenance costs.

In addition to these, this system has many more advantages.

All manufacturers in the automotive sector produce new generation vehicles under the titles of "efficiency" and "environmentalism", and electric power steering is a result of these titles;

They use lighter hardware that minimizes engine power loss (which means lower fuel consumption) and takes up less space.

Types of Electric Steering Systems

Electro-Hydraulic Steering System (contains electric hydraulic pump instead of mechanical hydraulic pump)

2. Electromechanical Steering System (Electric Power Steering and Servotronic Steering)

- Electric motor that rotates the steering shaft (the electric motor rotates the steering shaft)

- Electromechanical steering with double pinion (electric motor drives the rack directly)

- Electric Steer (Steer by wire: Wired steering. Electronic driving without mechanical connection. Not widely used yet)

If we sort in terms of fuel economy and technology used;

Hydraulic steering system; Fuel consumption is high, speed sensitive steering is difficult to apply, there is no automatic parking.

Electrohydraulic steering system; Fuel consumption is less than power steering, speed sensitive steering is easier to apply, there is no automatic parking system.

Electric steering: Fuel consumption is minimal, speed sensitive steering and automatic parking system can be applied.

Steering systems commonly used in new generation vehicles are: electro hydraulic steering system and electric steering system.

Features and Structure of the Electric Steering System

In this system, an electric motor increases the power (torque) of the steering shaft in addition to the steering force of the driver (auxiliary), so that steering is the most difficult to turn such as stop-slow driving-parking-maneuver, and the amount of turning is the most needed.

In the moments when it is heard, the steering wheel can be controlled more smoothly and comfortably.

As the rotational speed of the wheel (tire) decreases, the resistance created during the wheel (steering) increases; that is, the additional (servo) power requirement is higher.

As the load increases, the speed decreases, and therefore the friction resistance increases; Steering makes it difficult to control the wheels, so the need for extra power increases in order to keep the steering smooth.

In electromechanical steering, the steering is hardened as the speed of the vehicle increases; This increases driving safety at high speeds. As the rotational speed of the wheel (tire) increases, the frictional resistance that occurs during steering control decreases; that is, there is no need for additional (servo) power.

Thanks to this developed system, the electric steering system does not need any additional equipment to adjust the steering hardness, but the hydraulic system requires additional equipment.

In electromechanical steering, hydraulic equipment has been completely eliminated, ie not used.

Since there is no hydraulic pump in the electromechanical steering system, this system does not absorb engine power, it only uses the electric current when the steering wheel is turned. Thus, fuel is saved.

Thanks to the electromechanical steering; It has been possible to use an automatic parking system (parking assistant).

Under the command of the steering wheel electronic control unit (Steering ECU), the steering wheel can be turned and the vehicle can park itself.

Automatic parking assistance system is not possible in vehicles with hydraulic or electro-hydraulic steering, since there is no steering control unit.

Again, with the development of this steering wheel, it was possible to use a lane tracking system.

Likewise, thanks to the unit and sensors that control the steering system, the steering wheel is intervened and the vehicle remains in the lane.

After turning the steering wheel, the electric steering system helps the steering wheel to collect and move to straight position automatically.

In order to detect the direction of steering maneuver and turning force, a torsion shaft is used in the system as in the previous systems.

Torsion shaft; It works in conjunction with the steering position sensor and torque sensor.

What Are The Advantages Of Electric Steering System?

- Lower fuel consumption,

- Less parts (oil, pump, hose, valve, cylinder, etc.),

- Simpler structure, lighter and takes less space (compact structure),

- More comfort and better driving safety

In the hydraulic steering system, hydraulic pressure is generated by a hydraulic pump, the pump takes its motion from the engine (crank), which puts an extra load on the engine, causing more fuel to be burned.

The electric steering has no hydraulic pump, only an electric motor.

Therefore, there is no extra load on the engine.

In the power steering system, whether the steering is turned or not, the hydraulic pump continues to operate and draws power from the engine, increasing fuel consumption; however, the electric motor in the power steering consumes electrical energy only when the steering wheel is turned.

On average, only 10% of a passenger's steering wheel is turned, and no steering maneuver is required for 90%.

When the vehicle is stationary or when parking-maneuvering, the most needed support force is more difficult for the power steering to provide, because the engine speed is also low at this time, ie the speed of the pump, the system cannot produce high enough hydraulic pressure. For this reason, the steering wheel may not be soft enough.

There are too many parts in the power steering. This situation; It means excessive weight, taking up a lot of space and excessive cost. In the electric steering; Less parts, less space, less cost, easier maintenance.

In the hydraulic steering system; New generation technologies such as automatic parking system (parking assist) or lane tracking system cannot be applied.

What Does Electric Power Steering Mean?

In the automotive industry, "servo" is a term used in the sense of additional power and additional support, based on the principle of obtaining larger forces with a small force.

From the term power steering; It should be understood that this steering system is equipped with an auxiliary power equipment (electric or hydraulic). In power steering, an additional power source outside the driver supports the system with an additional force during the process of turning the steering wheel.

Therefore, we can call all non-mechanical steering power steering. Servo support; It is the application of a force in the direction in which the driver applies the force with the help of servos, in addition to the driver's steering force.

Electronic Steering Wheel Repair

How to Repair Electric Steering?

First of all it is Before starting to treat a patient, it is necessary to listen to the vehicle user before starting the steering repair, to test drive and to perform the necessary tests on the steering box with a steering tester.

The necessary data is collected by the steering tester and the defective part is learned. These defective parts are repaired.

Parts that are not repairable can be replaced with original or original parts according to your request.

After the problem has been resolved and the steering box is placed in its place, a test drive must be taken.

A few examples of steering gear malfunctions;

- Stuck when turning the steering wheel right or left

- Stiffness in the steering compared to the old - self-tightening

- The steering wheel is stiff in one direction

- Oil leak

- The steering wheel does not collect and stays on the side it turns

- Space on the steering wheel

For detailed information, please call us;

.webp?size=256)

Cihazı.webp?size=256)