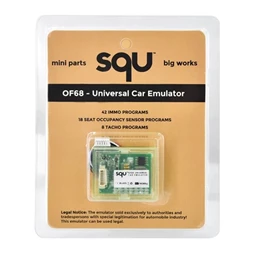

Indispensable Tools For Accurate Diagnosis: Testing Equipment Basic Vehicle Testing Equipment and Functions 1. Digital Multimeter (DMM) 2. Automotive Oscilloscope (Lab Scope) 3. Battery and Charging System Testing Equipment 4. Smoke Leak Detector (Smoke Leak Detector) 5. Injector Testing and Cleaning Devices 6. Pressure and Vacuum Meters 7. Sensor Simulators Accurate fault detection and repair of complex electronic and mechanical systems of modern vehicles requires much more than just a fault detection device (diagnostic scanner). While diagnostic scanners read error codes and provide an overview of systems, various specialized testing equipment is needed to find the root cause of the problem and verify the repair. Oscilloscopes, multimeters, battery testers, smoke leak detectors, injector testers and many other special tools are among the must-haves of a professional automotive technician. Dec. Having the right testing equipment shortens the diagnosis time, prevents unnecessary part replacements, improves the repair quality and, as a result, increases customer satisfaction. These equipment make invisible problems visible, providing technicians with precise and reliable data. In this comprehensive guide, we will examine in detail the basic test equipment commonly used in automotive services, what they work for, selection criteria and professional solutions offered by Nitro Bilişim. The test equipment that forms the basis of an automotive workshop and is most often used are: A digital multimeter is a versatile instrument used to make basic measurements in electrical circuits. If not, it is a must-have equipment. • Functions: Voltage (AC/DC), current (AC/DC), resistance, continuity (continuity), diode test, sometimes capacitance and frequency measurement. * Areas of Use: Finding cable disconnections, fuse control, measuring sensor voltages, charging system control, detecting grounding problems. * Selection Criteria: Measurement accuracy (accuracy), safety category (CAT rating), auto-ranging (auto-ranging), True RMS feature (for AC measurements), durability. The oscilloscope is a powerful diagnostic tool that graphically shows the change of electrical signals over time. It is ideal for analyzing the dynamic behavior of sensors, actuators and communication networks (such as the CAN Bus). * Functions: Displaying voltage waveforms, capturing signal anomalies (glitch, drop-out), ignition system analysis, injector spray timing, studying sensor responses. * Areas of Use: Detection of intermittent faults, verification of sensor performance, ignition system problems, CAN Bus communication errors. * Selection Criteria: Number of channels (usually 2 or 4 channels), bandwidth (MHz), sample rate (MS/s), triggering options, built-in automotive test library, ease of use. One of the most common reasons for a car not starting or electrical system problems is battery or charging system failures. • Functions: Battery voltage, starter current (CCA - Cold Cranking Amps) test, battery health status (SoH) and charge status (SoC) analysis, alternator output test, starter draw current test, diode leakage test. * Areas of Use: Detection of weak batteries, diagnosis of charging system failures (alternator, regulator), detection of parasitic current leaks. * Selection Criteria: Supported battery types (lead-acid, AGM, EFB, gel), test accuracy, ease of use, reporting feature (printer or digital). In vehicle systems (intake manifold, exhaust system, EVAP system, turbo hoses, etc.) are used to detect air or liquid leaks. It allows to visually determine the location of the leak by printing a harmless smoke into the system. • Functions: Pressure smoke generation, flow meter (some models), UV paint injection (some models). * Areas of Use: Vacuum leaks, EVAPORATION system leaks, exhaust manifold cracks, turbo system leaks, oil and coolant leaks. * Selection Criteria: Smoke production capacity, pressure adjustment, whether there is a built-in compressor, safety of use. Proper operation of fuel injectors is critical for engine performance, fuel efficiency and emission values. • Functions: Injector spray pattern test, flow quantity measurement, sealing test, resistance and inductance measurement, ultrasonic cleaning. * Areas of Use: Detection of blocked or defective injectors, comparison of the performance of injectors, extending the service life of injectors by cleaning them. * Selection Criteria: Supported injector types (gasoline/diesel, GDI, piezo, etc.), test pressure December, cleaning efficiency, automation level. It is used to measure various pressure and vacuum values, such as engine compression, fuel pressure, turbo pressure, intake manifold vacuum. • Functions: Analog or digital display, adapters for different pressure December. * Areas of Use: Detection of engine mechanical failures (compression leakage), fuel system problems, turbo system performance. They are devices that imitate certain sensor signals by tricking the vehicle ECU. It is used to determine whether a sensor is defective or if there is a wiring problem. • Functions: For different types of sensors (temperature, pressure, position, etc.) adjustable signal output. * Areas of Use: Sensor circuit diagnosis, control of ECU responses. Tips for Choosing the Right Testing Equipment * Determine Your Needs: Determine which equipment you should prioritize according to the types of failures you encounter most often and the types of vehicles you service. * Quality and Durability: Choose high-quality and durable brands designed for professional use. Cheap equipment can be more costly in the long run. * Ease of Use: The interface of the equipment should be understandable and ensure that technicians can use it quickly and effectively. * Training and Support: When you buy a new test equipment, it is important to get training on its use and choose a supplier from whom you can get reliable technical support. Nitro Bilişim offers training and support for all the equipment it sells. * Integration: Some test equipment can work integrated with diagnostic scanners or workshop management software. Such integrations can optimize your workflow. Be One Step Ahead in Diagnosis with Nitro Informatics Having accurate and comprehensive vehicle testing equipment is a basic requirement for the success of a modern automotive service. These equipments make it possible for technicians to diagnose faults more quickly and accurately, improve the quality of repairs and ensure customer satisfaction. Nitro Bilişim offers you a wide range of vehicle testing equipment (oscilloscopes, multimeters, battery test equipment, smoke leakage test equipment, injector test equipment and more) from industry-leading brands such as Autel, Launch, Topdon, Ecutest. Our expert team will be happy to help you choose the test equipment that best suits the needs of your workshop and use these equipment in the most efficient way. Choose Nitro Bilişim to be one step ahead in diagnosis.

Friday, May 16, 2025

.webp?size=256)

Cihazı.webp?size=256)